Site Seeing 201 | 2025

In the turbine hall of a power station, it was necessary to replace a concrete rail for a bridge crane and complete various paintwork and facade operations. During live operation. This meant that machines and control cabinets had to remain accessible during the renovation work. The work scaffolding, which measured approximately 3,000 m², therefore had to be precisely dimensioned, provide an easy-to-use working platform and also permit non-material-intensive assembly. The solution: Allround Scaffolding with Layher Lightweight technology.

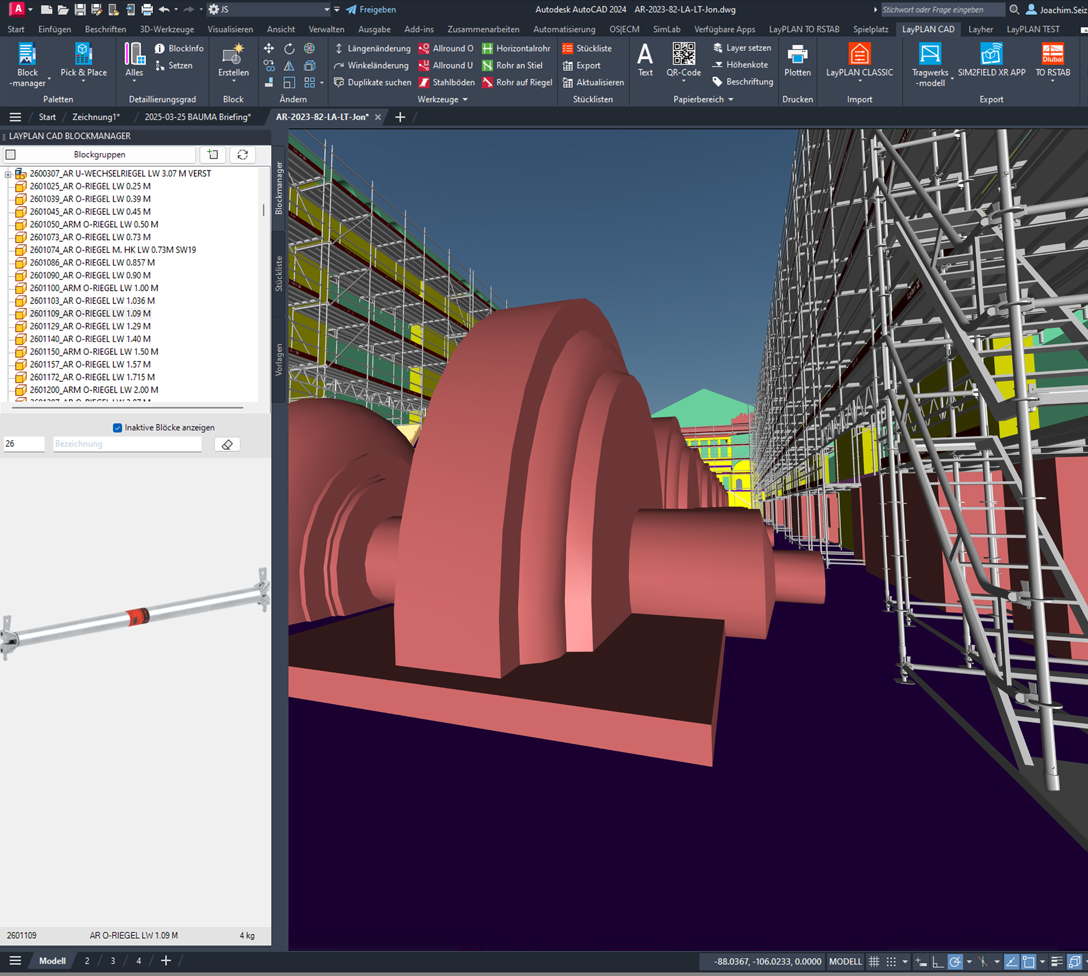

- Layher’s application engineers used LayPLAN CAD to plan the positions of the Allround standards in the 3D model of the power station in full compliance with the customer’s wishes.

- The combination of lightweight parts and high load-bearing capacities ensured rapid, material-saving assembly and efficient material transport – both manually and by trolley.

- The use of matching expansion parts within this system-based approach made it possible to comply with all site requirements: Size-70 Allround brackets for the cost-effective widening of the scaffolding in the 1.40 metre wide main bay, together with platform stairs for access up through the scaffolding

To prevent any risk of compromising ongoing power station operation and avoid expensive downtimes, the work scaffolding had to be planned precisely in advance. For example, one requirement was that all the control cabinets had to remain accessible. That is why Layher’s application engineers used LayPLAN CAD to plan the scaffolding in the 3D model of the power station – making it possible to position the Allround standards exactly as the customer required.

The Layher Lightweight technology of the modular Allround Scaffolding was successfully adapted to the power station operator’s specifications, while assembly demanded only low material volumes thanks to the high load-bearing capacity and low parts weights. This simplified not only construction but also the transport of the material. This had to be moved entirely by hand and trolley inside the turbine hall, because the bridge crane was unavailable for the duration of the renovation work.