Shipyard & Offshore

The benefits

for you

Time-saving.

Time-saving assembly, modification or dismantling thanks to sophisticated solutions and high fitting accuracy.

Safety.

High level of work safety thanks to AutoLock function and advanced guardrail options.

Easy-to-handle.

Ergonomic working thanks to lightweight and easy-to-handle individual parts.

Economical.

Economical because it is durable

and flexible in use.

Only one standard.

Only one standard for free-standing and suspended scaffolding.

Layher Shipyards and Offshore Solutions

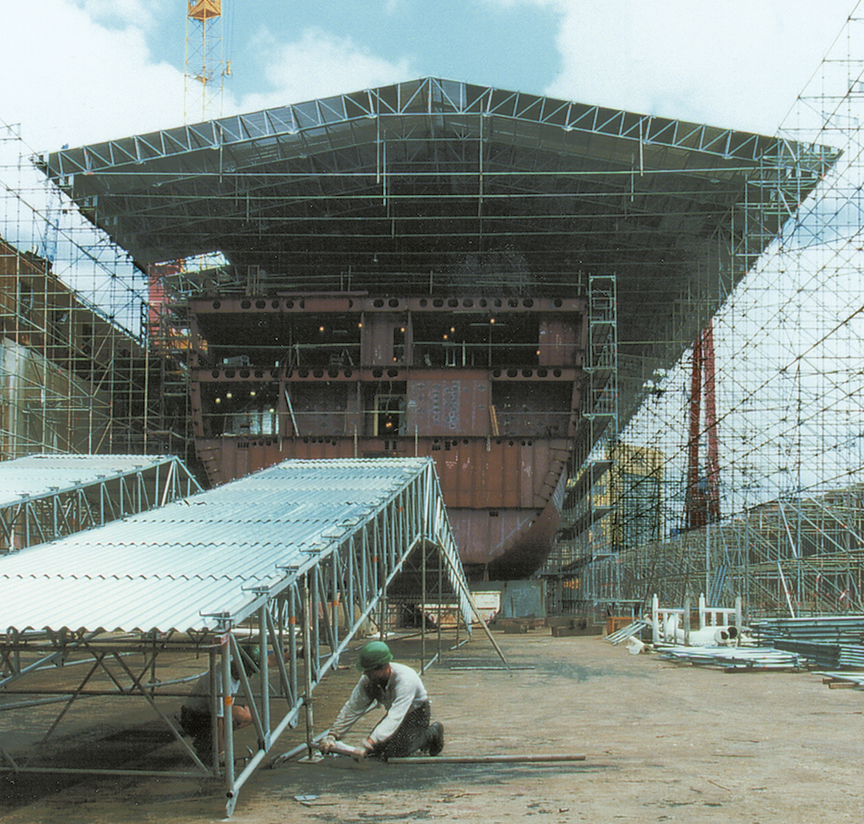

Simple geometry adaptation thanks to flexible angle selection on the Allround Scaffolding rosette.

Scaffolding decks in specific designs such as round, trapezoidal or triangular for ideal adaptation to ship‘s curved hulls, on the propeller and rudder, on the superstructure or inside the cargo area.

Extensive selection of bracket solutions for cantilevers or cantilever assembly for larger bridging. With a large variety of lattice girders, the aluminium FlexBeam or the Allround FW System, suitable solutions are also available for even more complex cantilevers or bridging applications.

Flexible and ergonomic access options with stairs – mounted in front or integrated.

Access decks made of various materials up to load class 4 with low weight are available for confined spaces.

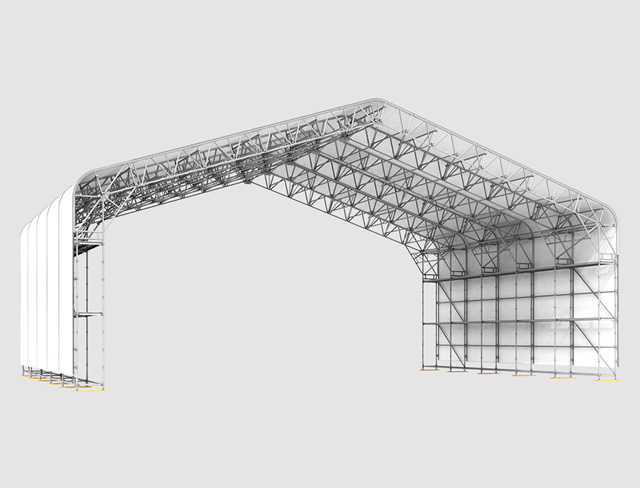

The adaptable and modular Layher roof systems provide enormously strong interim weather protection – suitable for any scaffolding system – with spans of more than 30 m and corresponding load bearing capacities. Only few different system components keep the investment costs within limits.

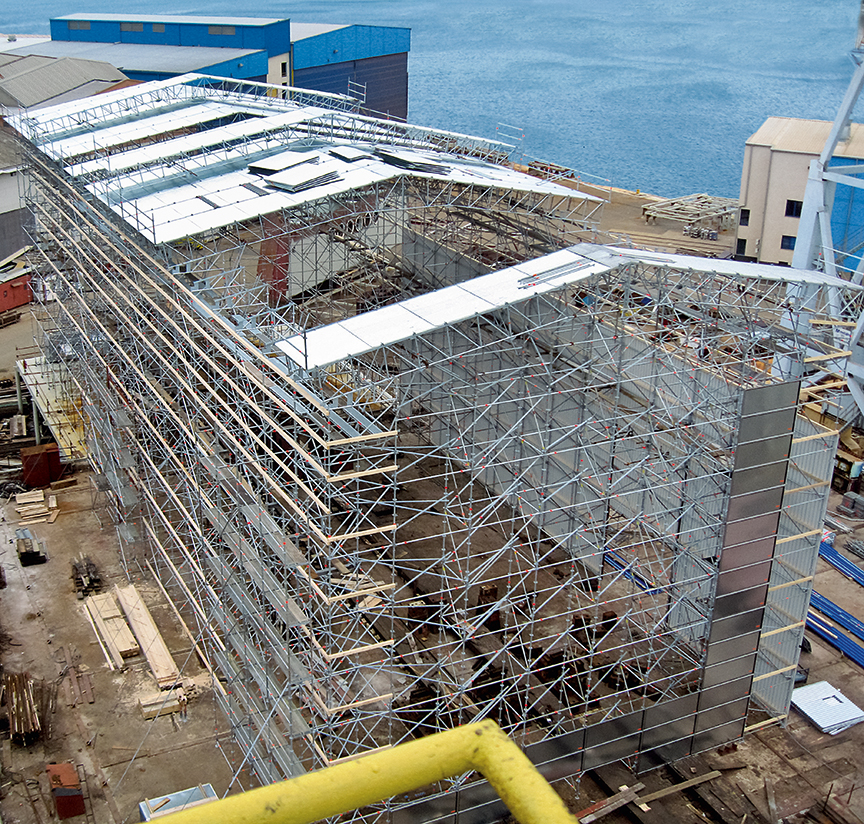

Whenever top protection is required, e.g. asbestos clearance, sandblasting

work or weather protection, Layher Protect System is the perfect solution.

With ingenious detail solutions, and usable with SpeedyScaf and Allround equipment, this unique system offers protection and safety both inside and outside.

In order to reduce the fire load, e.g. during welding work, wood can be completely dispensed with in the scaffolding.

Various components made of aluminium or steel are available for this purpose.

When the work areas are very high up, standard scaffolding structures can often be uneconomical due to high material and labour costs. With Allround Scaffolding, suspended solutions can be achieved without any problem in such cases.

To transfer tension-loads, standards can be connected to each other with hinged pins or by bolting them together.

For increasing the load capacity and to reduce the suspension points, different products can be chosen for almost every requirements: the Aluminium FlexBeam or the Allround FW System.

To meet the challenges of offshore and shipyards apllication, specific attachment components e. g. for suspension on pipelines or on steel beams are available.

Digital project planning with SIM

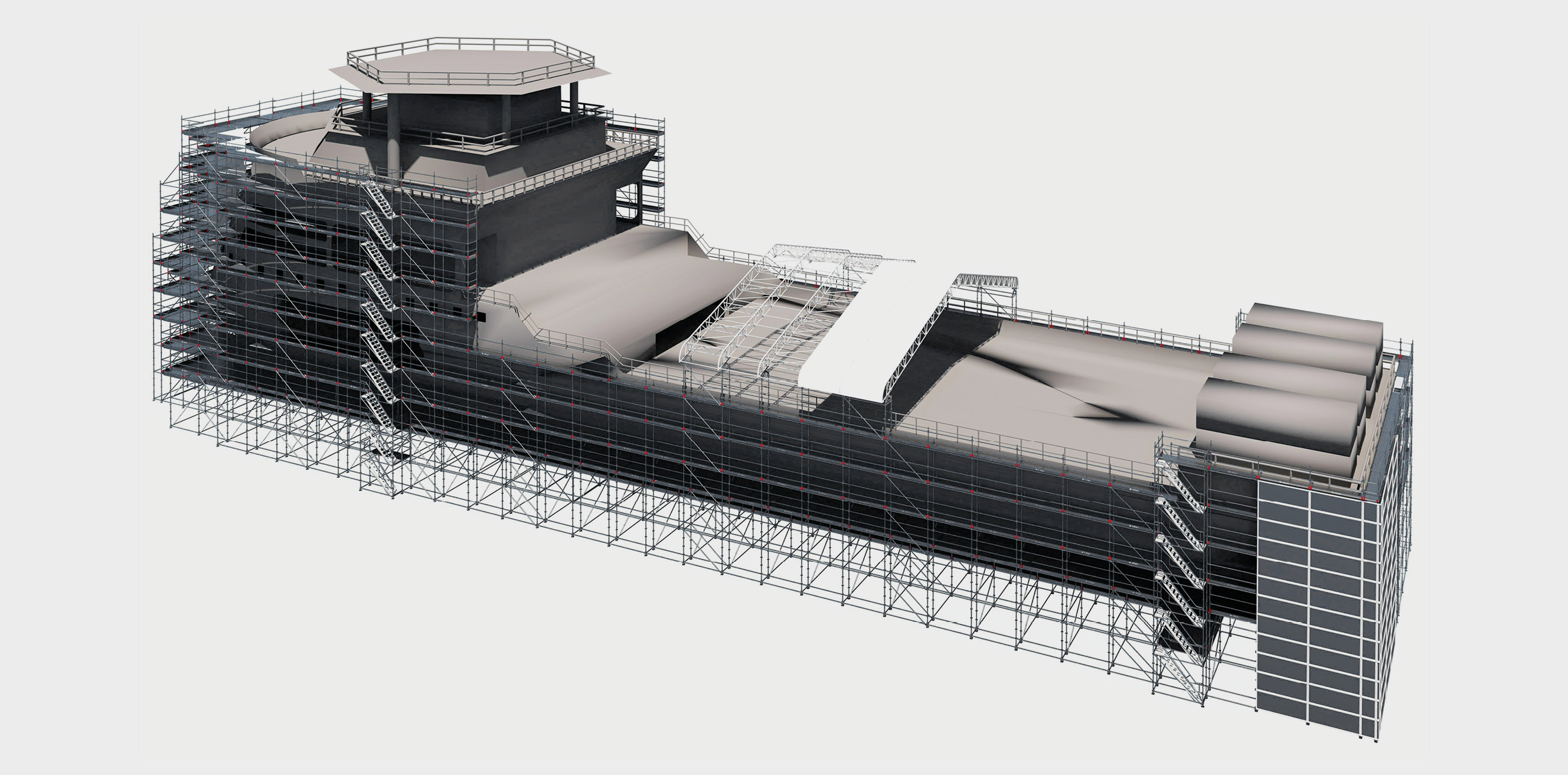

Layher SIM – Scaffolding Information Modeling

Scaffolding Information Modeling – SIM for short – is a process based on 3D models that was developed by Layher specifically for the requirements of shipyards and offshore solutions. You see what

you get and can make decisions

and changes, if necessary, at an

early stage of construction.

scaffolding

construction is

digital – and

its name is SIM