Site Seeing 206 | 2025

From the real world to digital scaffolding planning – and back again

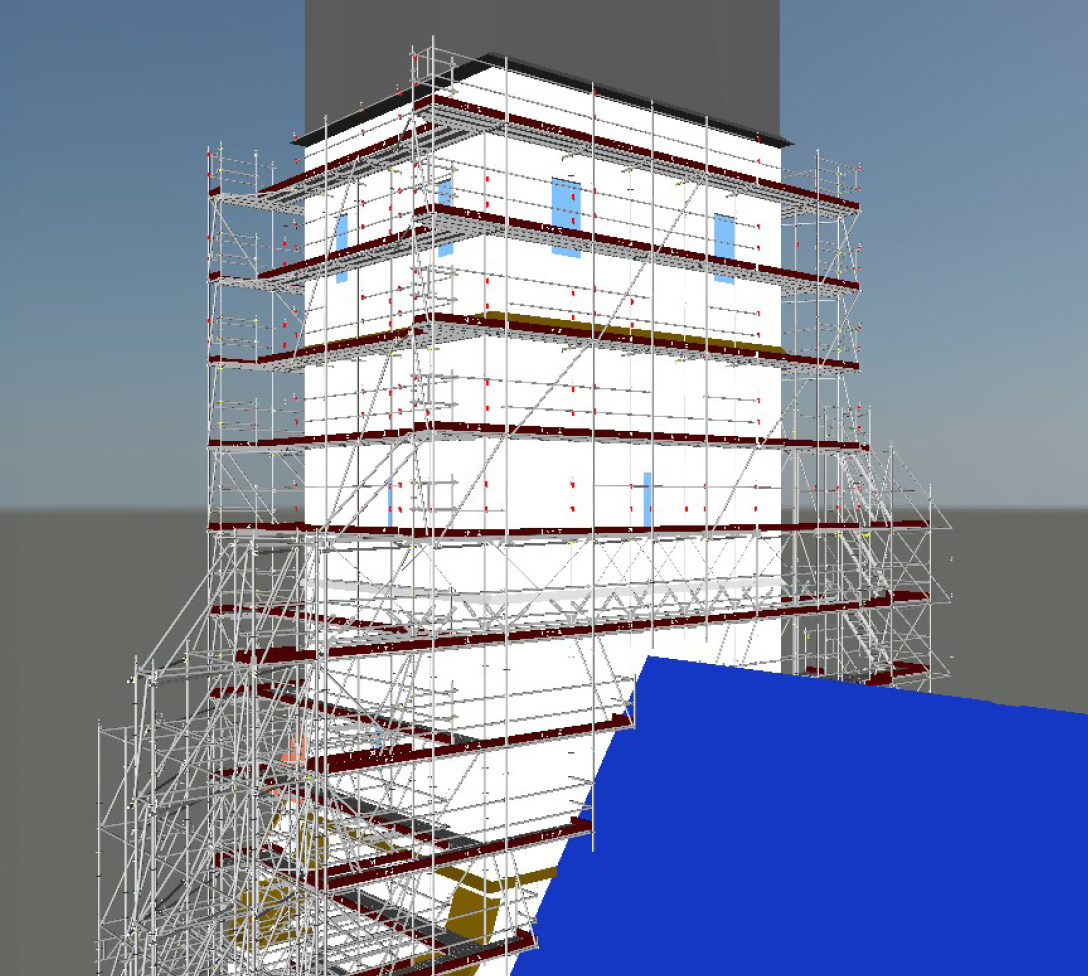

For scaffolding constructors JL Gerüstbau, the task of putting up scaffolding around the Liebfrauenkirche church in Mettingen near Esslingen involved a number of challenges. The 15th century listed building has a complex geometry, and the roof of the nave lacks the necessary load-bearing capacity. What’s more, the church stands right in the middle of the town. The support surface available for the scaffolding was therefore very limited. That is why company management not only chose the Integrated Layher System, but also took advantage of the benefits of digitalisation – from a 3D scan of the historic building through 3D scaffolding planning to precision measurements with the digital service SIM2Field. The result was high-precision and cost-effective assembly.

- Digital mapping of the real-life situation via a 3D scan accurate to the nearest millimetre provided the basis for subsequent detailed 3D scaffolding planning with LayPLAN CAD

- Material-saving, slender substructure made from Allround Scaffolding with Lightweight technology

- Bridging structure above the nave constructed with the high-strength Allround FW System

- Further construction faster and safer using the modular access system AGS

- Simple implementation of on-site requirements using expansion parts matching the system: Allround brackets to adapt to the building geometry, Allround platform stairtower for fast and sure-footed access through the scaffolding

- Transfer of digital planning back to the real world with SIM2Field – digitally assisted layout using a total station. Because the substructure had been measured to the nearest millimetre, it was possible to lift in the Allround FW structure by crane in just a few minutes

3D planning with LayPLAN CAD permitted detailed advance planning of the complex scaffolding structure. Once created, the 3D planning also provided a template for generating the material lists in LayPLAN MATERIALMANAGER as well as for the structural analysis. To do this, the 3D scaffolding model was simply transferred to the frame analysis program using LayPLAN TO RSTAB – together with all the relevant structural data.