Site Seeing 207 | 2025

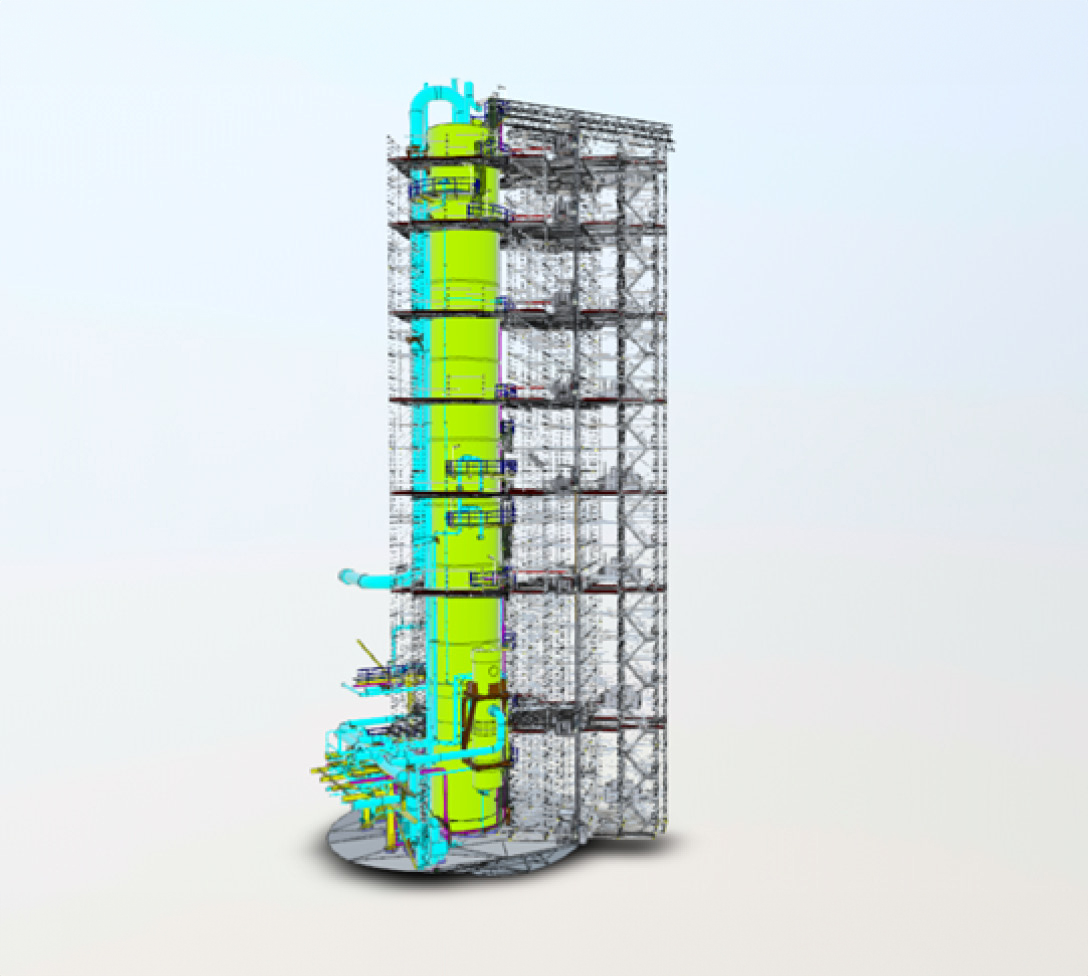

The installation of 88 trays in a methanol refinery needed complex work scaffolding for a 60 metre-high column. There were two central requirements here: material-saving and hence rapid assembly, to minimise cost-intensive downtimes. And a high degree of safety for the various jobs at great heights. The solution was Allround Scaffolding in Lightweight technology with matching supplementary components.

- Flexible geometry adjustments using Allround Scaffolding, to prevent conflicts with piping and also to permit crane emplacement of the approximately 6 metre-long trays

- Material-saving and hence economical bridging between parts of the structure, using the high-strength aluminium FlexBeam. Scaffolding decks are easily attached here

- Safer and more efficient working on the column, thanks to contour-matching decking with the aid of 45° steel decks

- Allround platform stairtower for safer ascent and descent on site

- Careful digital 3D planning in advance using LayPLAN CAD

Layher’s applications engineers digitally planned this complex work scaffolding in advance using LayPLAN CAD. This permitted a scaffolding structure that was both material-saving and optimally matched to the geometry of the column. The digital scaffolding twin was agreed upon in close consultation with the clients during the planning process. Following approval, dependable material lists were generated from the 3D plans at the touch of a button. This meant that the material needed was in the right quantity in the right place – an important factor in preventing expensive site stoppages in industry.