Sustainability

Layher is geared towards sustainable business practices

A central role in this is played by people, the environment, and the management of raw materials.

Building and maintaining properties is unthinkable without scaffolding.

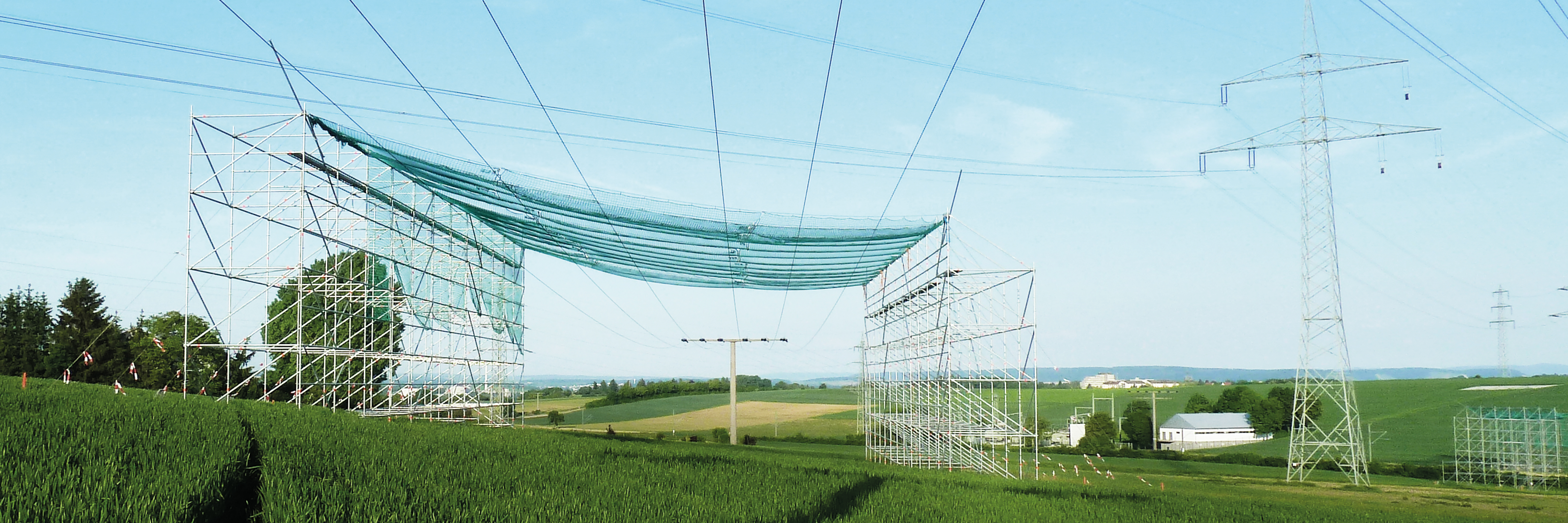

Layher scaffolds are essential for the construction of many key components of our infrastructure for living and working. The sustainable transformation of our economy and society also relies on these products. Layher provides scaffolds as tools for change. They support, for example, in areas of transformation such as the energy sector, building renovations, and new technologies.

Scaffolding

is

the

key

is

the

key

Considered product design for sustainable orientation.

Long product lifespan and value retention.

Products that can be used and combined across generations.

Layher Lightweight: Efficient resource use and improved material handling.

Use of recyclable materials such as steel or aluminum.

Sustainability in practice

Efficiently use resources

Protect the environment

Take social responsibility