Site Seeing 209 | 2025

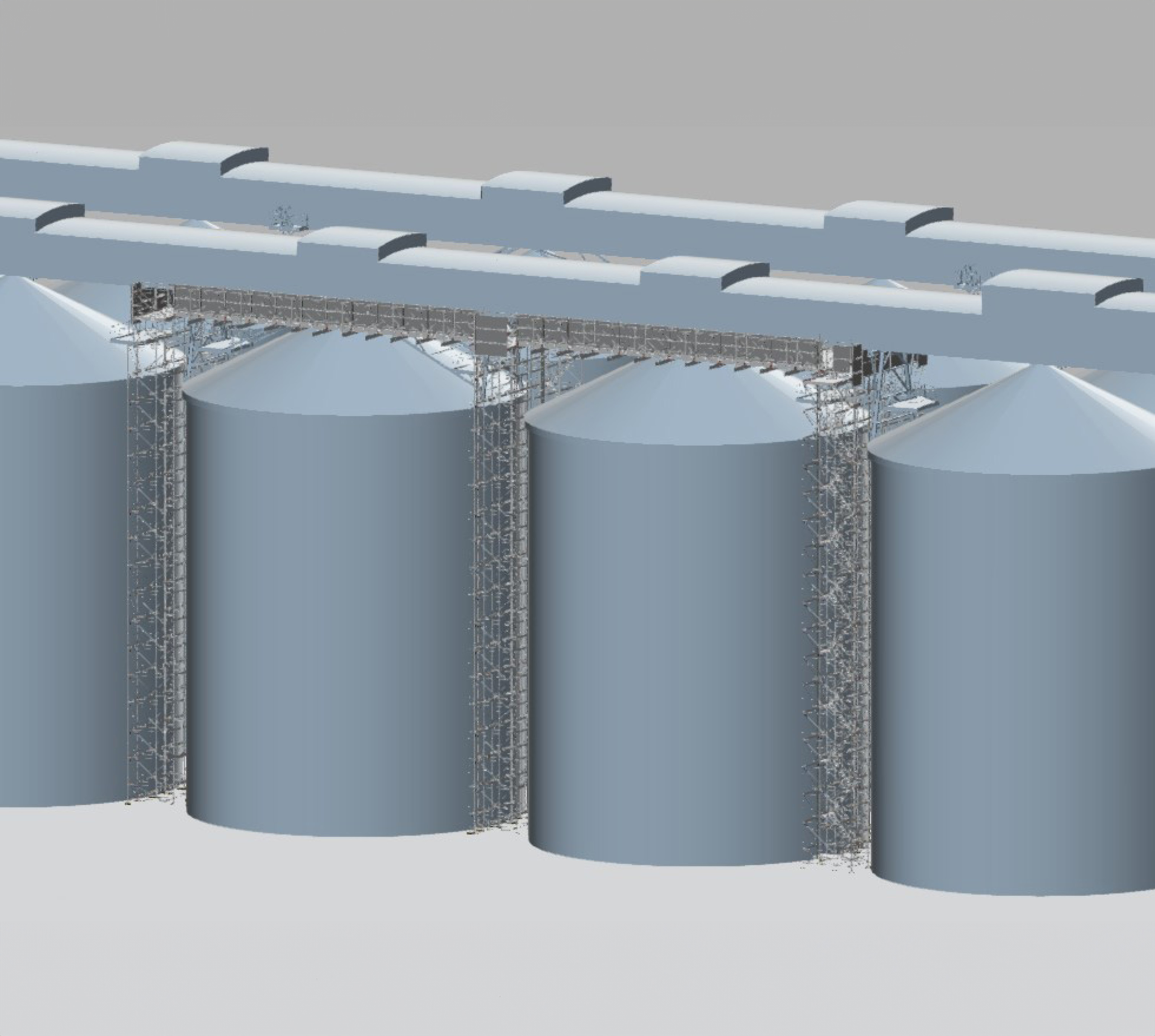

Scaffolding takes to the air – a smart combination of beam solutions

The steel structure of the gallery above several silos of a major cereal cooperative first had to be sandblasted over a length of 100 metres and then repainted – at a height of more than 30 metres. That was made possible by a material-saving and hence economical bridging structure made using Layher’s beam solutions: the Allround FW System and the aluminium FlexBeam. A solution with a system.

- Precise planning using 3D in LayPLAN CAD, plus close consultation with the client based on the digital twin of the scaffolding

- Building of supporting structures made from Allround Scaffolding between the silos

- Faster and safer assembly on the ground of clear-span bridging structures using the Allround FW System, followed by lifting them into place on both sides of the gallery by crane

- Connection of the bridging structures to the aluminium FlexBeam underneath the gallery – thus ensuring that fewer suspension points were needed and decks for the work platform were also easy to lay

- Cladding of the bridging structures with the Protect System for protection of the gallery during work

- Training of local scaffolding erectors by Layher’s training engineers during initial deployment of the beam solutions, plus on-site support

Layher applications engineers planned the entire structure in advance and digitally in 3D using LayPLAN CAD. This enabled the solution to be optimally adapted to local conditions – such as high wind loads – and to the geometries. As a result, conflicts were prevented.