Aircraft maintenance

The benefits

for you

Modular.

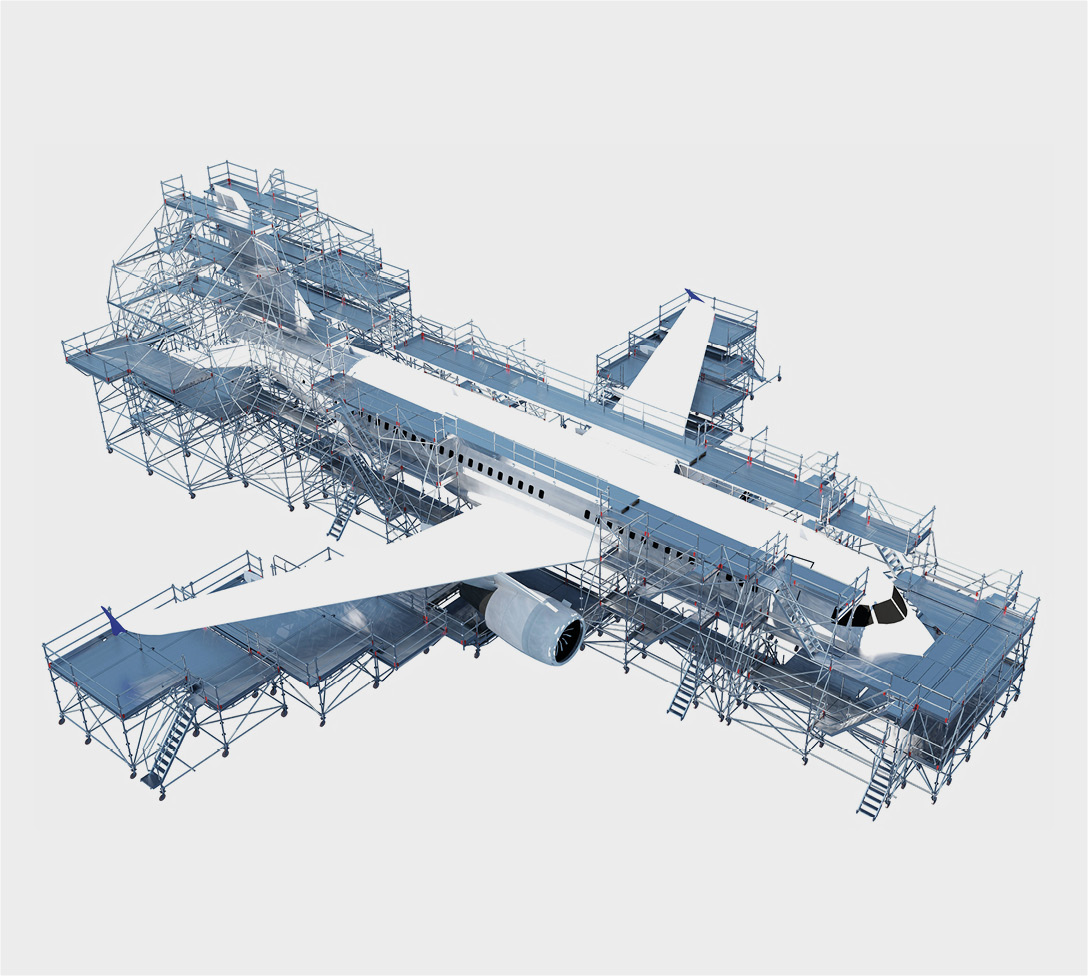

Modular design – universal adjustment to every type of aircraft and follows every contour Modular design – universal adjustment to

every type of aircraft and follows every contour.

Flexible.

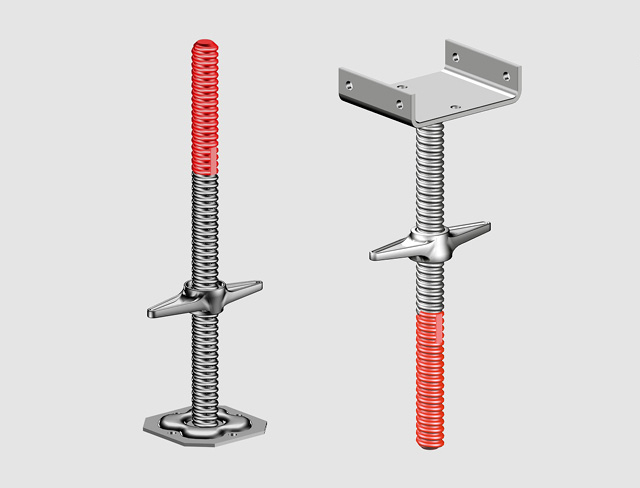

Height adjustment for flexible heights and access.

Efficient.

Ideal working environment for safe and efficient maintenance, repair

and overhauling.

Quick.

Quick assembly and dismantling – quick docking and undocking.

Mobility.

Modules are quick to position thanks to mobility.

Adaptable.

One system adaptable for all types

of aircraft.

Optimal accessibility.

Convenient work conditions with continously decked work surfaces

and stairways for easy access.

Expandable.

System can be expanded at any time.

Space saving.

Space saving storage possible.

Sustainable.

Long lasting investment – ready for future changes and requirements.

Layher Aviation Solutions

Ensures repair, paint and maintanance work of the aircraft‘s horizontal stabilizer, vertical stabilizer and the rudder – with high safety.

For access to the aircraft flap and fuel systems. It can be easily adapted to the wings inclination. Also cut-outs in the work surface for engines are possible.

Stairs can be positioned to your needs.

Access to leading edge and trailing edge, wing tips, engine and adaption to height.

It ensures access for painting and maintenance work all around the fuselage.

It can be constructed as compact rolling structure or as complete fuselage dock around the whole aircraft body.

By using the Layher docking systems, it‘s also easy to get access for mounting WIFI units on aircrafts fuselage.

Access to windshield, radome, doors, nose wheels etc.

Possible structures as single section or double section and also mobile solutions available.

Non-slip decks ensure firm stand even on inclined working levels.

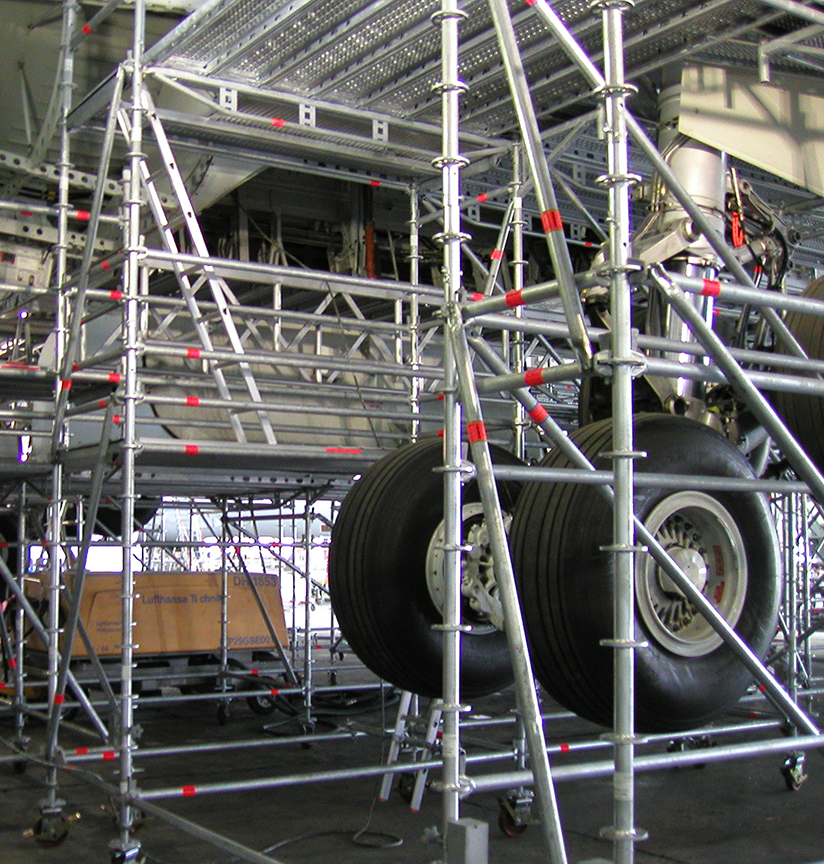

For work at the landing gear or other parts at the lower part of the fuselage, underbelly docks with inclined work surfaces and cut-outs e.g. for wheels are possible.

Safe working at exactly the required height optimises the working conditions.

Proven in aviation applications

SAS - High-Speed WiFi installation

OLT Express - Airbus A320 painting - Timelapse

Planning and scheduling certainty at sites

Dependable 3D planning of Aircraft Docking Systems without collisions with the aircraft is just one of many benefits. Added to that are the realistic visualisation, allowing work to be coordinated with other trades, for maintenance, repair, checks and overhauling.

Benefits for you:- Transparency in all work steps and cost control

- Planning and scheduling certainty at every project

- 3D digital planning for a modular system guarantees best possible adaption to each aircraft type and to your needs

Layher SIM – Scaffolding Information Modeling

Scaffolding Information Modeling – SIM for short – is a process based on 3D models and designed by Layher to meet the specific requirements of designing a Aircraft Docking System. You see what you get and decission and changes can be made, if necessary at an early stage of the design.

in maintenence docks planning is digital – and it’s name is SIM