Site Seeing 217 | 2025

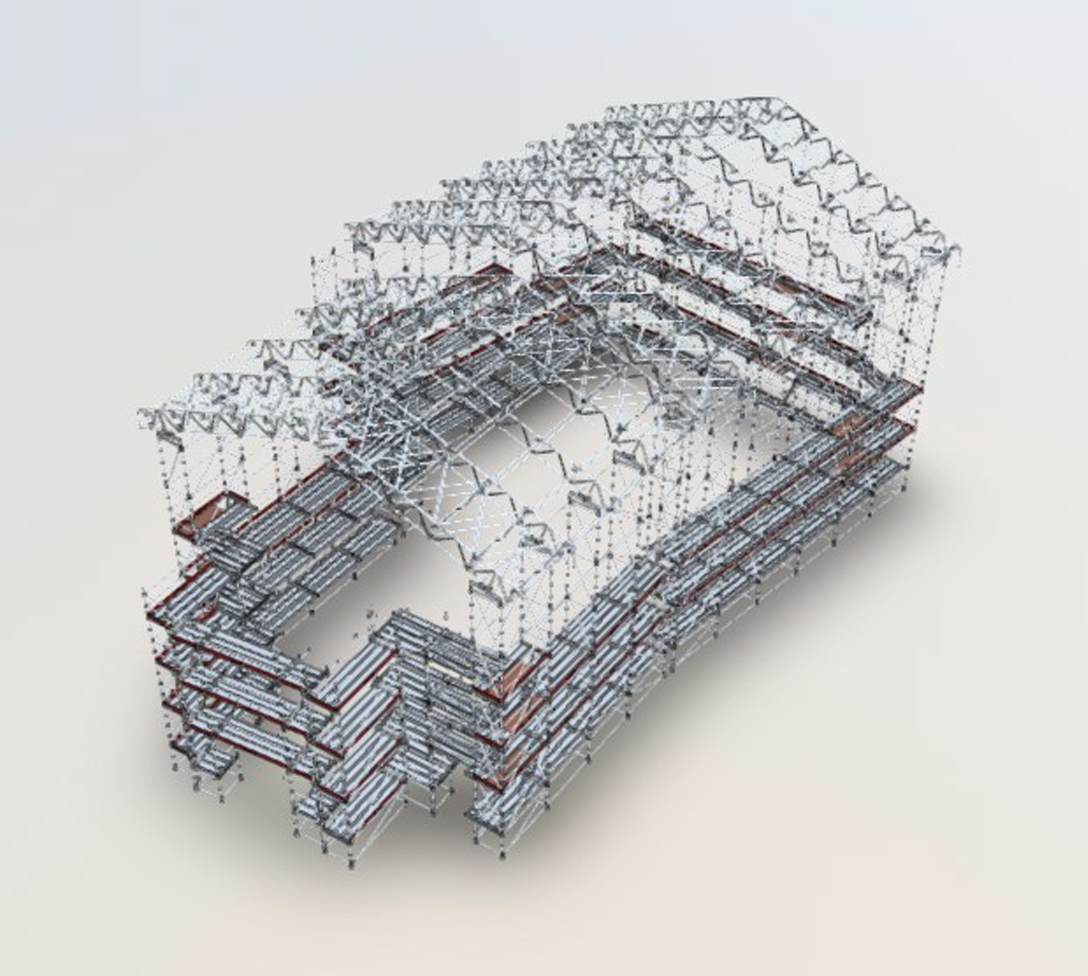

When old buildings have to be renovated in historic cities, simple work scaffolding is usually not enough. Instead, the site also has to be protected and aesthetics are crucial. A current example: The renovation of the Church of the Transfiguration of Our Lord in Tallinn (Estonia) during the winter months. The task called for flexible facade scaffolding because of the curved shape of this medieval abbey church with a Baroque iconostasis dating back nearly 300 years. What is more, the site had to be enclosed to make it possible to work independently of weather conditions and also to protect passers-by: The most economical solution? A combination of Allround Scaffolding, Keder Roof XL – and digital preliminary 3D planning.

- Thanks to this advance 3D planning using LayPLAN CAD, it was a straightforward task to adapt the work and support scaffolding to the curvature of the church.

- A reliable list of materials could then be generated at the touch of a button via LayPLAN MATERIALMANAGER. The scaffolding company was then able to obtain the missing parts quickly from the local Layher service centre.

- The Allround System was used for the work and support scaffolding. This system permits geometrical adjustments to the scaffolding thanks to the flexible choice of angles when attaching the components and the range of different standard lengths.

- Thanks to the different bracing variants available, the Keder Roof XL is also suitable for on-site use during the winter, while simultaneously creating a pleasing appearance in Tallin’s historic city centre.

Layher’s application engineers planned the facade scaffolding in 3D, together with the enclosure with the Keder Roof XL, in advance using LayPLAN CAD.

This permitted precise adaptation to the curved shape of the historic church as well as coordination with the client on the basis of the digital twin of the scaffolding.

The scaffolding structure was planned in advance in 3D. That allowed close consultation about the structure between the construction company Meyer, the engineering company Schumacher and the Layher applications engineers using the digital scaffolding twin.